|

| June 04, 2019 | Volume 15 Issue 21 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Joining: Options for attaching fiber-reinforced plastics to metal

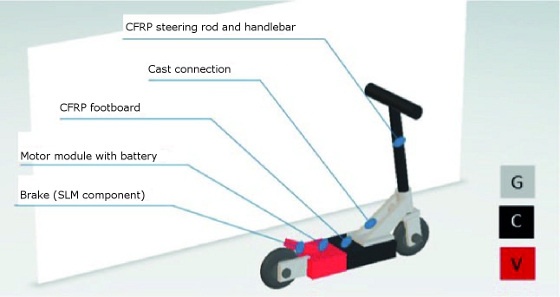

Fraunhofer researchers run through some smart solutions to join carbon fiber-reinforced plastics and metal. They use a simple electric scooter design to provide application and technique examples. [© Fraunhofer IGCV]

Designing and building lightweight vehicles challenges manufacturers to combine functional metal components with lighter-weight, highly durable carbon fiber-reinforced plastics. Researchers from the Fraunhofer Institute in Germany have developed a variety of solutions for joining such disparate materials -- including one where resin melts into and surrounds a metal plate.

When looking at electromobility as a main propulsion tech for the future, one of the biggest hurdles is how to increase vehicle range -- whether that be an electric scooter, bike, motorcyle, car, or truck. Besides better battery tech, a lot of it will depend on making vehicles as light as possible, because the lighter the vehicle, the longer the energy stored lasts. In this design sphere, carbon fiber-reinforced plastics, or CFRP for short, are a current material of choice. CFRPs are as strong as steel and eight times lighter -- even three times lighter than aluminum.

But electric vehicles will not be made of solely CFRPs, so joining these materials to metals is a must -- and a challenge. The general practice is to manufacture individual components, the vehicle frame for instance, using CFRP, and then join them to the function-bearing metal components using screws or adhesives. Components that connect long expanses and transfer loads can be manufactured using CFRP, while metal is reserved for the functional components and attachment points for the steering mechanism, for example.

Researchers from the Fraunhofer Research Institution for Casting, Composite, and Processing Technology (IGCV) at the Technology Center in Augsburg, Germany, have come up with a variety of techniques (some are improvements to standard ways, and at least one is new and novel) to join conventionally cast components with those made of CFRP. Looking beyond the thoroughly established foundry technology, they say there is also a lot of potential to get the job done by incoporating modern manufacturing techniques such as additive manufacturing and 3D printing.

To highlight their methods, the researchers are using a simplified scooter as an application demonstrator.

Hybrid metal and carbon fiber-reinforced plastic e-scooter. [© Fraunhofer IGCV]

"We've combined the various new joining techniques, says Dr.-Ing. Daniel GŁnther, who heads the project at Fraunhofer IGCV. "The goal is to cut down on the number of mechanical attachment points and simplify the joining process as much as possible."

"There's a lot of potential in combining metal and CFRP components, with a potential weight savings of up to 50 percent, depending on the part," he says.

Smart use of materials. G= Casting; C= Composite; V= Processing Technology. [© Fraunhofer IGCV]

Clamping technique to join rear-wheel support

The rear-wheel support of an electric scooter contains a lot of parts integral to its functioning and, for that reason, it is made out of metal. To make it as lightweight as possible, the research team produced the part out of highly durable steel, optimizing the topology so the material is restricted solely to the places it is needed to support the required functions.

To produce the part, researchers drew on an additive manufacturing technique that uses a laser beam to form components out of a metal powder. The rear-wheel support is connected to the CFRP footboard using a screw system, making it easy to remove and disassemble for maintenance.

Adhesively bonded hybrid steering head

The steering head of the scooter is a hybrid component, with an aluminum base frame linking to the footboard behind and the handlebars at the front. This part of the scooter is full of parts integral to its functioning, with a significant expanse to bridge in between. Using CFRP parts ensures the necessary rigidity.

The two different materials are joined together using adhesive bonding. "In terms of a baseline load, we assumed a person weighing 100 kilograms performing jumps with the scooter. To support that sort of load using a pure aluminum cast part, you would need a huge amount of material to ensure sufficient rigidity," says GŁnther.

To manufacture the part, GŁnther and his team began by analyzing the available installation space. As a rule of thumb, the more room used, the larger the cross-section of the component -- and the better its rigidity. The material has to be kept as thin as possible, however, to ensure that the component does not become overly heavy. The solution to this is to use CFRP in combination with cast metal. As a further step, the researchers calculated the load at various points of the component. The splices have been precisely positioned at the points with the least load. Rigidity is guaranteed thanks to the shaping of the CFRP component.

New "fork" system: The joining technology of the future?

The load-bearing capacity and durability of CFRP comes from the fibers contained within it. Here, the main challenge lies in transferring the force acting on a component so it is absorbed by these same fibers. On top of this, engineers need to ensure that any metal parts are as securely attached to the CFRP components as possible, without any gaps or cavities.

As a solution, the researchers have developed a completely new joining technique. For the electronic scooter application, there is a cylindrical piece connecting to the handlebars, a steel component made using an additive manufacturing technique. The bottom of the component has a plate that works as a base with small pins sticking out from its surface.

Connecting piece prior to lamination, showing the novel pin structure that helps create a positive bond with the CFRP prepreg. [© Fraunhofer IGCV]

The researchers overlayed this base plate with the prepregs for the CFRP component, made out of fibers coated with synthetic resin. Afterwards, they applied a vacuum and increased the temperature. In this process, the resin encloses the carbon fibers, flows downward, and closes the gap with the metal plate, hardening to form an adhesive bond.

Using this method, not only does the resin stick to the plate, but the protruding pins are also enveloped and held in place by the fibers. This interlocks the components and supplies a solid bond -- without the need for screws or additional adhesives.

"The technique is fast, industry-ready, and can easily be scaled up for mass production," says GŁnther.

Source: Fraunhofer Institute

Published June 2019

Rate this article

View our terms of use and privacy policy